ZnSe Optics for Pyrometry

| Download CVD-ZnSe Optics for Pyrometry Datasheet (PDF, 195 KB) |

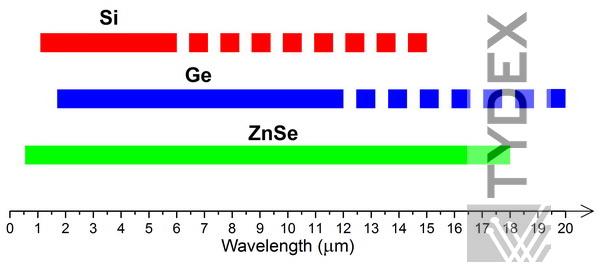

Pyrometry is a method to measure temperature from a distance. It is based on measuring thermal radiation flow from an object. The peak flow wavelength can be determined by equation λmax = 3000/T (μm), where T is the temperature of the object measured in degrees Kelvin. For a human body the radiation peaks around 10 μm, for a campfire around 3 μm, for a welding arc - 1 μm, for the Sun - 0.55 μm. For most objects the main thermal energy is radiated in near and middle IR region. That’s why the majority of pyrometers are equipped with optical components made of IR-transparent materials, such as Silicon, Germanium and Zinc Selenide. The wider is the transparency region of the instrument’s optics, the more universally applicable is the instrument and the more accurate are the measurement results. Zinc Selenide with its transparency between 0.55 and 18 μm can be considered undeniably superior to Silicon and Germanium. Fig. 1 shows transparency regions of all the materials mentioned above.

Fig. 1. Transparency regions of Si, Ge, and ZnSe.

For more details on optical properties of CVD-ZnSe, refer to the CVD-ZnSe material section.

Optical transparency of Zinc Selenide in the visible region gives it an additional advantage, namely, the ability to adjust the optics “by eye” with a red laser.

Relatively low dispersion of ZnSe refractive index and low importance of focusing quality in pyrometry usually allow to disregard chromatic aberration.

Zinc Selenide is much less sensitive to temperature variations than germanium. For example, germanium becomes completely opaque at 100°C, Zinc Selenide does not manifest noticeable absorption at this temperature.

The same advantage Zinc Selenide selenide the best choice for high-power laser optics.

In comparison with many IR materials (such as AMTIR and salts) ZnSe is physically and chemically durable enough to manufacture relatively thin parts and it places virtually no restrictions on operational environment (except strong acids).

Tydex produces a wide variety of CVD-ZnSe optics for pyrometry: windows, lenses, beam splitters etc. Applying various anti-reflection coatings one can achieve high optical transparency in a wide range that is very important for pyrometry.

Other coatings (anti-reflective, beam-splitting or highly reflective) are also aviable.

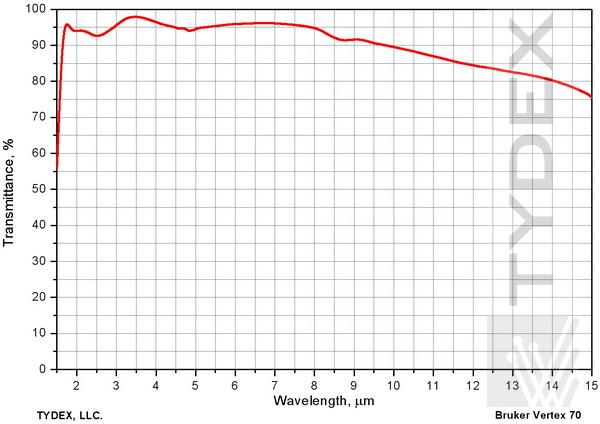

The raw materials undergo incoming inspection for ensuring the high quality of the components. Transmission spectrum of the coated optical component is also recorded. Typical transmission spectrum of a Zinc Selenide window with AR coating is depicted in Fig. 2.

Fig. 2. Transmission spectrum of a CVD-ZnSe window, dia. 120x10 mm, two-sided anti-reflection coating for 3-12 μm range.

For detailed description of spectral control of the components, refer to the article Germanium Windows and Lenses for Thermography.

For more information please fill in our Request form.

Optics is ready to be shipped!

Optics Stock

Shipment/ Payment/ Warranty ...