Atypical Components

| Download Atypical Components Datasheet (PDF, 373 KB) |

Tydex specializes in manufacturing of custom-made optical components. Fairly often they look like catalogue' equivalents proposed by well-known companies in this field but sometimes they are so amazingly atypical that to have them produced we are forced to utilize special technological approaches and improvements. Such our products are intentionally emphasized here and placed to this specially introduced chapter. It is pleasure for us to pay your attention to similar optics and thus to demonstrate high level of production excellence and experience of our specialists in solving non-standard tasks of our customers.

1.Sapphire lightguides for medical applications

Such lightguides are widely used in medical set-ups for the purposes of human' skin treatment to reach positive therapeutic effect for epilation, tattoo removal, and so on. The introduced lightguides are of rectangular parallelepiped shape. All their surfaces including chamfer areas are good optically polished. In fact they are relatively massive optical windows transmitting radiation and allowing light to incident on a patient skin.

Overall dimensions of working surfaces (both opposite ends) are designed mainly taking into account the features of the medical set-up as well as a size of an area expected to be under treatment. But the overall length of the lightguide is assigned taking into account the most convenient handling since rather long section is located into doctor' wrist similar to a pen during writing process.

Deferential peculiarities of these parts are that they are completely polished and one end which during treatment procedure is directly contacting human' skin (so called “patient end”) has the increased chamfers of rounded shape both at corners and along facets. Such special chamfer' design allows to avoid appearance the scratches, eliminate skin injury and thus to execute therapy in extremely safe and very soft manner.

During the last several years we have supplied more than one thousand similar sapphire lightguides of various overall dimensions. The lightguides with the following sizes: 10х20х25mm, 10x20х50mm и 20х20х50mm are available from stock.

Specification:

| Material | Optical grade sapphire |

| Tolerance zone for overall dimensions, mm | +/-0.25 - typical +/-0.05 - achievable |

| Non-parallelism of any opposite surfaces, arc. min. | < 3 |

| Perpendicularity, arc. min. | +/- 30 |

| Surface quality, src/dig: -working surfaces (both ends) - the rest four surfaces - rounded chamfers |

40/20 60/40 80/50 |

| Surfaces accuracy, fringes: - working surfaces (both ends) - the rest four surfaces |

<=1 <=4 |

| Chamfers | rounded, have special and safe design |

2. CVD-ZnSe Dual-Focus Lenses for cutting of thick materials

Dual-focus lenses (DFL) are a revolutionary new type of lens for CO laser cutting. DFL are intended to be used as a direct replacement for conventional lenses in some industrial laser systems and applications.

Basic principle of the lenses coming from their title lies in existence of a couple of focal points. Complex design of these lenses allows distributing incident laser energy and delivering its fixed fraction into a secondary (lower) focus.

Especially designed to assist in a range of thick-section cutting jobs such lenses give the following advantages:

- processing of increased thicknesses at a given power;

- increased process speed;

- elimination of upper and lower surface dross;

- immediate cut-initiation;

- educed assist-gas usage;

- improved process control.

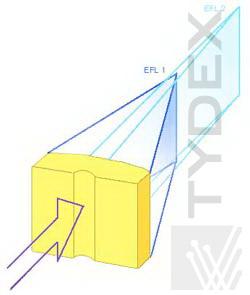

Fig. 1. DFL working principle.

Tydex proposed and has been using a novel approach in fabrication of DFL, which in particularly did allow to create DFLof cylindrical shape.

The Alternative custom designs request specification below presents standard product. sizes and are available upon request.

Specification:

| Type | Dual-focus lense |

| Material | CVD-ZnSe |

| Overall dimensions, mm | 25.4 (+0/-0.25) x 25.4 (+0/-0.25) |

| Thickness, mm | 4.0 (+0.5/-0.0) |

| EFL tolerance @10.6 um μm, % | +/- 2 |

| Stripe width, mm | 4 (+0.5/-0) |

| Surface quality, scr/dig | 60/40 |

| Surface figure, fringes | < 8 |

| AR coating reflectivity per surface@10.6um, % | < 0.5 |

Fig. 2. Cylindrical DFL working principle.

Tydex has supplied more than ten cylindrical DFL with the following EFL combinations: 127&254 mm, 169&254 mm.

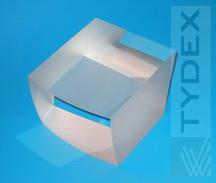

3. Big glass prisms for scanners

Such prisms are utilized in the scanners and other complex devices mainly to obtain information about an object. One of the application areas is dactyloscopy. Here the identification of a person becomes possible and is executed as a result of investigation of relief (papillary) lines which are given by separate fingers or a human palm as a whole. Complexity of manufacturing of such prisms consists in their large overall dimensions. Combination of the flat and spherical surfaces which are located from each other under a certain angle (differ from 90 degrees) makes production very complicated as well. The presence of inclined surfaces required by application unfortunately does not allow having single basing surface and dictates necessity of its change when the polishing of spherical and flat surfaces is alternating. The fact that these prisms can not be “blocked" at the same polishing block during manufacturing run makes production process isolated from others and practically hand-made.

Main requirements to such devices at this moment are enhancement of resolution and improvement of object' quality. Due to multiple internal reflections of the light in these prisms its optical path may exceed distance as long as 1 meter. All above dictate severe requirements to quality of the glasses used for production. It is clear that to get better performance the material should not include internal defects and possess by minimal dispersion and inhomogeneity of refractive index. To meet it for production of such prisms we have been using foreignorigin glasses and intentionally avoid gluing of prism' parts, so the products are monolithic items made of high-quality optical glasses. To apply anti- and high-reflection coatings on such prisms where they are dictated by specification, we had to upgrade coating chamber otherwise it could not be done in principle. In particular, taking into account big prisms' overall dimensions both a registration system and holders were moved down from their regular sites. First is used for control of deposited materials and measuring of coating layers' thicknesses but the latter is necessary to hold the prisms during the coating process.

А. Four-fingers scanner prism

Fig. 1. The foto of the scanner prism and dactyloscopic print of four fingers of left human palm.

B. Palm scanner prism

Fig. 2. The foto of the scanner prism and dactyloscopic print of right human palm.

For quotation and delivery please fill in our request form.

Optics is ready to be shipped!

Optics Stock

Shipment/ Payment/ Warranty ...