M1 and Crystalvision Colorless Sheet Glass

| Download М1 and Crystalvision Datasheet (PDF, 620 KB) |

Sheet glass is a product of the glass industry, widely used in various applications. Sheet glass is produced in much higher volumes than optical glass, and its manufacturing requirements are not nearly as strict.

Sheet glass is produced by two methods, the Pittsburgh process and the float glass process. The quality of glass produced by these methods is controlled according to the standard GOST 111-2014. The majority of sheet glass is currently produced by the float process. It involves pouring a molten quartz-lime mixture into a tub of molten tin. The mixture forms flat sheets on the surface of molten metal. According to the GOST 111-2014, thickness variation for 2 mm thick glass shall not exceed 0.1 mm for all grades of sheet glass. The glass mix is protected from the environment by a nitrogen-hydrogen atmosphere. The required thickness is achieved by controlling the area covered by the molten glass.

Depending on optical aberrations, defects, maximum thickness deviation and variation, sheet glass is divided into М0, М1, М4 and М7 grades. The lower the grade number, the fewer defects are acceptable, and therefore the better quality of the glass. M0, M4 and M7 grade glass is less commercially available. M4 and M7 grades are generally not produced separately, but are assigned to glasses whose parameters are worse than those of M1 glass. Therefore, we use M1 grade glass.

In actual practice, due to the float manufacturing method, the as-manufactured surface quality of sheet glass corresponds to 20/10 – 40/20 scratch/dig according to MIL. Per our measurements, the thickness variation of 50x50 mm plane-parallel plates 4, 6 and 10 mm thick is in the range of 3-15 μm. Smaller variation can be achieved by polishing.

Besides M1 grade sheet glass, Tydex processes low-iron float Crystalvision glass, including the application of optical coatings. Crystalvision glass is clarified by reducing its iron content. It leads to reduced light absorption and increased light transmittance in the visible and near IR spectrum.

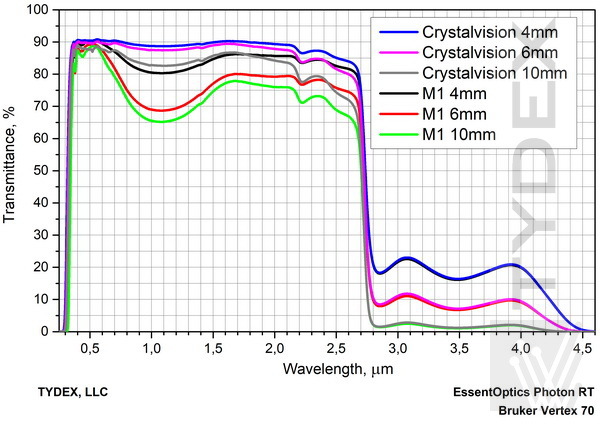

Fig. 1. Transmittance comparison of M1 and Crystalvision glasses of various thickness.

Fig. 1. Transmittance comparison of M1 and Crystalvision glasses of various thickness.

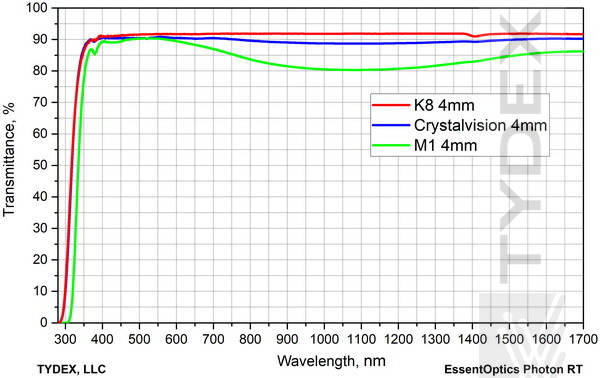

Fig. 2. Transmittance comparison of M1 and Crystalvision glasses with K8 optical glass.

Compared to optical glass, M1 and Crystalvision are characterized by lower transmittance in the visible light range. However, in the absence of strict requirements for transmittance in that range, they can be used as a replacement for optical glass. In addition, the aforementioned glasses can be enhanced with BBAR (Broadband anti-reflection), reflective, electrically conductive ITO (Indium tin oxide) and other coatings. Due to its high transparency and conductivity, the ITO coating can be used as thermal protection for optical elements.

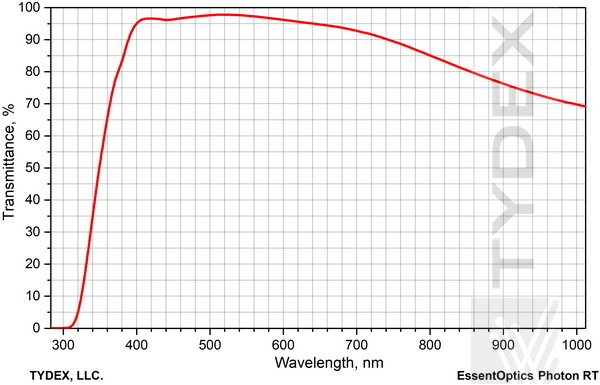

Fig. 3. Transmittance spectrum of M1 glass with BBAR antireflection coating (400-700 nm).

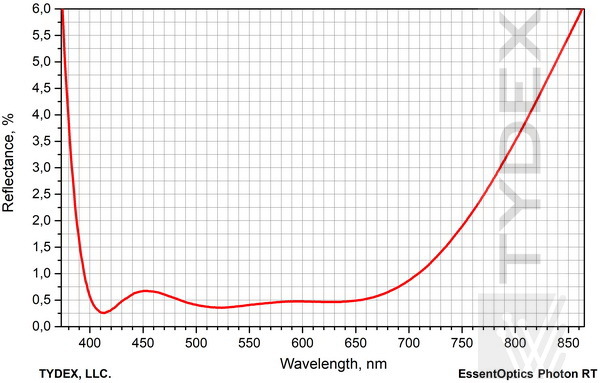

Fig. 4. Reflectance spectrum of M1 glass with BBAR antireflection coating (400-700 nm).

Physical characteristics of glass brand M1:

| Characteristics | Reference value | |

| Density (at 18 °C) | 2500 kg/m3 | |

| Knoop hardness HK 0,1/20* | 6 | |

| Compressive strength | 700-900 MPa | |

| Tensile strength | 30 MPa | |

| Design cross-breaking strength | 15 MPa | |

| Young modulus | 7•1010 Pa | |

| Poisson ratio | 0.2 | |

| Softening point | 600 °C | |

| Thermal linear expansion coefficient (temperature range -40 to 300 °C) | (7-9)•10-6 К-1 | |

| Thermal stability | 40 °C | |

| Thermal conductivity coefficient | 1 W/(m•К) | |

| Specific heat | 720 J/(kg•К) | |

| Thermal transmittance | 5.8 Вт/(м2•К) | |

| Emission coefficient | 0.837 | |

| Refractive index | 1.5 | |

| Directional reflectance | 0.08 | |

| * Per GOST ISO 9385 | ||

Physical characteristics of glass brand Crystalvision:

| Characteristics | Reference value | |

| Density (at 18 °C) | 2500 kg/m3 | |

| Knoop hardness HK 0,1/20* | 6 | |

| Young modulus | 7•1010 Pa | |

| Poisson ratio | 0.2 | |

| Shear modulus | 29 166 N/mm2 | |

| Mohs hardness | 5-6 | |

| Softening point | 725 °C | |

| Melting temperature | 1300 °C to 1600 °C | |

| Thermal linear expansion coefficient (temperature range 20 to 300 °C) | 9•10-6 К-1 | |

| Specific heat | 720 J/(kg•К) | |

| Emission coefficient | 0.837 | |

| Refractive index (λ = 589.3 нм) | 1.50 | |

| * Per GOST ISO 9385 | ||

Tydex performs primary treatment and polishing of M1 and Crystalvision glass. We also apply optical coatings to parts of various shapes and sizes made of these materials. The maximum dimension of finished polished items (with or without optical coating) is 250 mm. Manufacturing of larger parts can be performed on a case-by-case basis in cooperation with our partners. Available thicknesses are 2, 3, 4, 5, 6, 8, 10 and 12 mm for M1 grade glass and 4, 6, 8, 10 and 12 mm for Crystalvision glass.

Please note that we do not supply sheet glass blanks but only finished products.

Optics is ready to be shipped!

Optics Stock

Shipment/ Payment/ Warranty ...